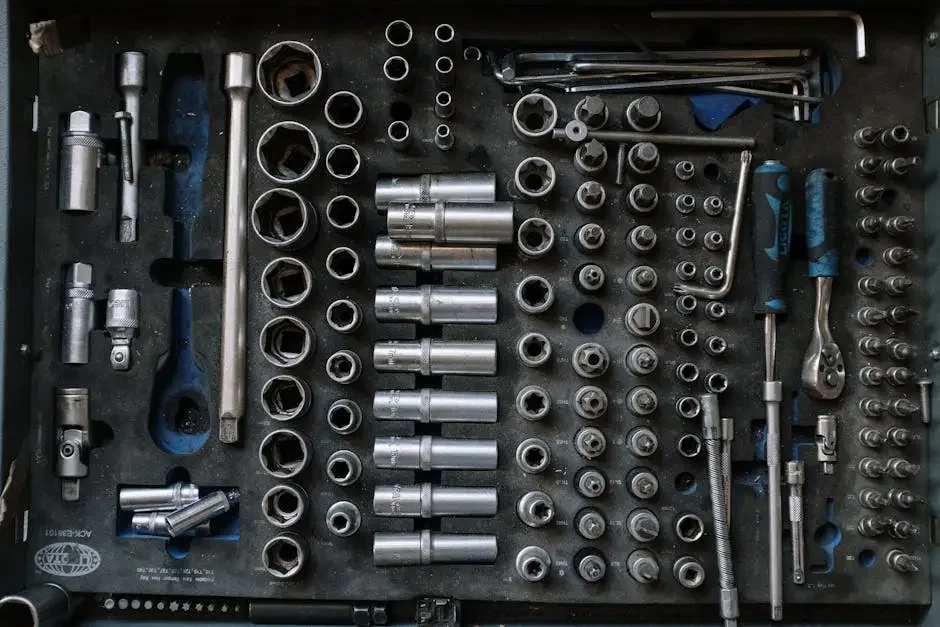

9 Essential Cylinder Honing Tools for Your Garage

If you're diving into the world of engine rebuilding, having the right tools is essential. Cylinder honing is a crucial part of this process, and understanding what tools you need will make your job easier and more efficient. In this article, we’ll explore nine must-have cylinder honing tools that every garage should have to get the perfect finish on those cylinders.

1. A Quality Cylinder Hone

The cornerstone of any honing setup, a quality cylinder hone is designed to remove material from the cylinder walls and create a surface that promotes proper ring seating. Look for adjustable models to suit different cylinder sizes. A good quality hone can last for many uses, making it a worthwhile investment for any garage enthusiast. By understanding the different types available, you can select one that best matches the specifications of the engines you typically work with, ensuring that you always get a smooth finish.

When choosing a cylinder hone, consider the size of your most common projects. Some hones cater specifically to small block engines, while others might handle larger applications. You'll want to assess ease of use as well—many modern hones come with features like automatic alignment that simplify the process significantly. By carefully evaluating these aspects, you can set yourself up for honing success time after time.

2. Honing Oil

Using honing oil during the honing process not only decreases friction but also helps to remove debris and keep the honing stones cool. A good honing oil will extend the life of your tools and improve the quality of your work. Think of it as the lubricant for your honing journey; without it, you risk damaging both your tools and the cylinder.

Furthermore, selecting the right honing oil can greatly affect your final results. For instance, some oils provide additional properties that assist in preventing rust or other corrosive issues during storage. Keeping a few varieties on hand allows you to adapt to different materials and conditions as needed. Make sure to check compatibility with your honing stones, too—you want them to work together for the best outcome.

3. Measuring Tools

Accurate measurements are key to successful honing. Calipers and micrometers will help you measure cylinder diameter and wall thickness, ensuring that you achieve the desired specifications. It's vital to understand that the slightest error in measurement can lead to significant issues down the line.

In practice, having a digital micrometer can make your job even easier. These tools often feature display options that help you read measurements quickly, reducing the risk of human error. Moreover, taking measurements frequently during the honing process allows you to correct any inconsistencies on-the-fly, ultimately leading to a superior finish.

4. Deburring Tool

After honing, a deburring tool will help smooth out any sharp edges left on the cylinder's surface. It's essential for preventing potential wear and tear on engine components. While honing removes material effectively, it can also leave behind small burrs that may go unnoticed yet wreak havoc over time.

Having a reliable deburring tool allows you to easily address these issues, ensuring that your cylinder is not just polished but genuinely ready for operation. Plus, the process is quick and straightforward—an invaluable step that can save you from future complications.

5. Air Compressor

An air compressor is invaluable for blowing out debris and cleaning the cylinder after honing. Keeping your workspace clean is crucial for the quality of your work. Using compressed air can help you reach every nook and cranny, ensuring that all particles are removed before you proceed to the next step.

Moreover, an air compressor can be used for various tasks beyond just honing. From inflating tires to cleaning sensitive components, this versatile tool can come in handy in multiple ways. Its presence in your garage represents not just efficiency but also a commitment to maintaining the high standards of your projects.

6. Variable Speed Drill

A variable speed drill is perfect for controlling the speed during the honing process, ensuring you achieve a fine finish. This level of control can make a significant difference in the outcome of your honing job. While it might seem like a small detail, being able to adjust your speed according to the material can lead to a noticeable improvement in results.

Think about the range it provides; slower speeds are ideal for tougher materials, allowing for precise control, while higher speeds work wonders for softer surfaces. Additionally, ergonomic features on many drills ensure that you don't get fatigued, allowing for extended use without discomfort. This dual benefit enhances both your performance and the overall quality of your honing activities.

7. Honing Stones

Different types of honing stones are suited for various materials and finishes. Having a selection of stones will allow you to choose the best one for your specific honing needs. Whether you're working with cast iron, aluminum, or another type of material, there's a honing stone tailored just for that.

Not only do honing stones vary by material, but they also come in different grits to achieve various levels of smoothness. A versatile collection in your garage allows you to fine-tune your projects—switching stones based on the condition of the cylinder can optimize results and ensure long-lasting performance. Remember, investing in quality honing stones can save you time and headaches in the long run.

8. Protective Gear

Safety should never be overlooked in any garage work. Protective glasses, gloves, and masks will keep you safe from particles and dust during the honing process. It may feel somewhat tedious to gear up, but ensuring your safety is paramount.

Moreover, good protective gear can make the experience of honing much more enjoyable. You can focus on the task at hand without worrying about debris or fumes. Consider investing in high-quality equipment that fits well and is comfortable, as this will encourage you to take protection seriously every time you step into your garage.

9. Workshop Manual

Finally, having a workshop manual for the specific engine you’re working on can provide crucial guidance on honing specifications and techniques, ensuring that you follow best practices. This resource is your roadmap—the clearer it is, the more confidently you can navigate the honing process.

Don't underestimate the value of a well-organized manual; it can save you time and frustration by providing insights not just on honing but on engine assembly and maintenance as a whole. By consulting your manual, you can adapt your techniques to meet specific requirements, making each project far less daunting.