9 Common Myths About Main and Rod Bearings Debunked

There are a lot of misconceptions when it comes to main and rod bearings. Many car enthusiasts and even professionals have fallen prey to these myths, which can lead to misunderstandings and poor maintenance choices. In this blog post, we’re going to debunk some of the most common myths surrounding these essential engine components, providing you with the clear, straightforward information you need to keep your engine running smoothly.

1. All Bearings Are the Same

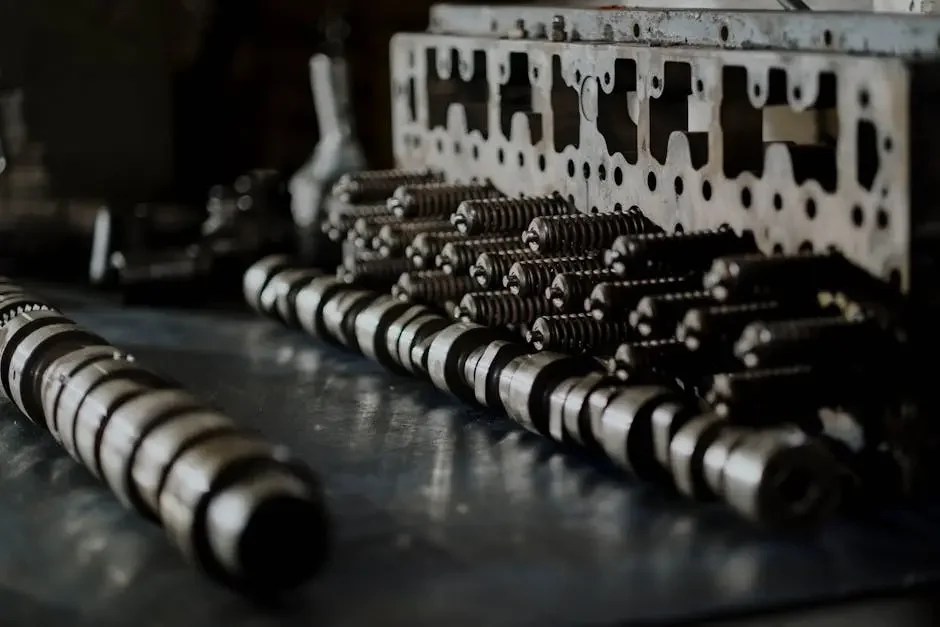

One of the biggest misconceptions is that all bearings serve the same function. In reality, main and rod bearings are quite different in design and purpose, tailored to their specific roles within the engine. Main bearings support the crankshaft and handle the engine's main load, while rod bearings connect the crankshaft to the connecting rods and manage the oscillating forces of engine operation. This distinction is crucial for understanding how these components work together to ensure a smoothly functioning engine.

The materials used in main and rod bearings also vary significantly, showcasing the manufacturers' intent to optimize performance and durability. Premium bearings often integrate advanced materials that withstand higher temperatures and pressures, ultimately enhancing engine performance. Thus, the notion that all bearings are interchangeable is not only misleading but could also result in incorrect installations and potential engine damage.

2. Higher Performance Means Lower Bearing Lifespan

Another myth suggests that using high-performance bearings will inevitably lead to a shorter lifespan. While it's true that increased friction and heat can affect longevity, quality materials and proper installation can maintain performance without compromising durability. Today’s advanced bearings are designed to handle higher RPMs and stress levels without significant wear, which challenges the stereotype that pushing your engine to new limits means sacrificing its integrity.

In fact, many enthusiasts have successfully utilized high-performance bearings in their engines for years without any issues. The key lies in choosing the right bearings that match not only the engine's specifications but also the intended use. Those who frequently race their vehicles, for example, should consult with experts to select bearings capable of enduring extreme conditions, ensuring that performance doesn’t come at the cost of longevity.

3. Bearing Clearance is Not Important

Some people believe that a little extra clearance in bearings won't matter. In reality, proper clearance is crucial for ensuring oil flow and reducing friction. This oversight can lead to detrimental consequences for engine performance and longevity. A small gap permits adequate lubrication to circulate freely, while too much clearance can cause oil to drop below the optimal level, risking significant wear and tear.

Moreover, the correct clearance varies according to the specific engine design and the intended application. Analyzing this aspect of engine assembly can often mean the difference between achieving smooth operation and facing catastrophic failure due to insufficient oil pressure or excessive heat generation. For those undertaking engine rebuilds, paying attention to bearing clearance should be a top priority.

4. You Can Skip Bearing Inspections

Many think that if the engine is running smoothly, there’s no need to inspect bearings. Regular inspections are vital for early detection of wear or damage. By the time symptoms become apparent, significant damage might already have occurred. In fact, routine inspections can save vehicle owners from costly repairs down the road, providing peace of mind along with performance.

Most drivers benefit from setting a schedule for inspections, albeit they might seem tedious at first. Regular checks can point out small issues before they escalate, making preventative maintenance a far better alternative to a full engine rebuild. Being proactive about bearing health ultimately allows for maintaining optimal engine performance and reliability well into the future.

5. Once Installed, Bearings Don’t Need Attention

This misconception can lead to catastrophic failures. Bearings require regular maintenance checks and monitoring for signs of wear throughout their lifespan. Once you’ve installed bearings, your responsibility doesn’t just vanish; it transforms into a commitment to uphold their health over time. Consistent observation of oil pressure and engine behavior can provide early warnings of potential problems, preventing a sudden breakdown.

Furthermore, during routine oil changes or services, paying close attention to bearings can offer insight into their condition. Don’t wait for an engine noise or low oil pressure warning light to mandate action; being vigilant allows you to enjoy a longer-lasting, healthier engine. Taking the time to check bearings is an investment in both performance and peace of mind.

6. Soft Bearings Aren’t a Good Option

While many believe that harder bearings are always better, softer bearings can actually provide superior performance in certain applications by absorbing shock and vibrations. This flexibility enables them to handle the stresses generated in specific operating conditions effectively. For instance, in high-performance applications where engine vibration is a significant concern, softer materials can enhance overall longevity and efficiency.

It's important to realize that the term 'softer' refers to the material's consistency and resilience, not overall quality. Many premium materials are specifically designed for high-performance scenarios where shock absorption is necessary. The key takeaway here is to choose bearing materials that align with your vehicle's needs rather than simply opting for harder materials under the assumption that they are superior.

7. Higher Oil Viscosity Means Better Protection

Some people think that thicker oil always offers better protection for bearings. However, too high of viscosity can actually reduce oil flow, leading to inadequate lubrication and increased wear. It's a classic case of 'too much of a good thing'—while thicker oils are great for high-temperature environments, they can also hinder efficient distribution, making them counterproductive.

It’s wise to follow manufacturer specifications when choosing oil viscosity for your vehicle. These guidelines are developed after extensive testing to balance protection and performance. Optimal viscosity correlates directly with the engine design, ensuring proper lubrication under all operating conditions. Therefore, an informed choice of oil can enhance both engine performance and bearing longevity.

8. Engine Rebuilds Don’t Require New Bearings

It's a common myth that you can reuse bearings during an engine rebuild. In reality, new engine bearings are essential for ensuring the longevity and reliability of your newly rebuilt engine. Bearing wear occurs over time, and even if the bearings appear acceptable upon visual inspection, relying on old bearings runs the risk of unexpected failures.

Investing in new bearings is a small price to pay for peace of mind, knowing that the rebuilt engine is set up for optimum performance. New bearings are specifically engineered to work with fresh components, which helps promote better compatibility and function. In this context, always prioritize new components whenever you undertake extensive engine work for better results.

9. Lubrication Isn’t a Major Factor for Bearings

Lastly, some might underestimate the importance of proper lubrication. Oil is the lifeblood of your engine, and without it, even the best bearings will fail prematurely. The right lubrication can reduce friction, manage heat levels, and extend bearing lifespan significantly. Therefore, making sure that your engine oil is at the correct level and suitable for your vehicle is crucial.

Moreover, understanding the role of oil additives can enhance your engine's performance further. Additives often serve as protective agents within the oil, optimizing its ability to do its job effectively. By investing time in understanding lubrication, you ensure that your main and rod bearings aren’t just surviving but thriving, enabling your engine to perform at its best.