Why Cylinder Honing is Essential for Engine Longevity

Cylinder honing plays a crucial role in the maintenance and performance of an engine. It’s not just a technical process; understanding it can significantly impact the lifespan and efficiency of your vehicle. This blog will elucidate the importance of cylinder honing, its process, and how it can contribute to the overall health of your engine.

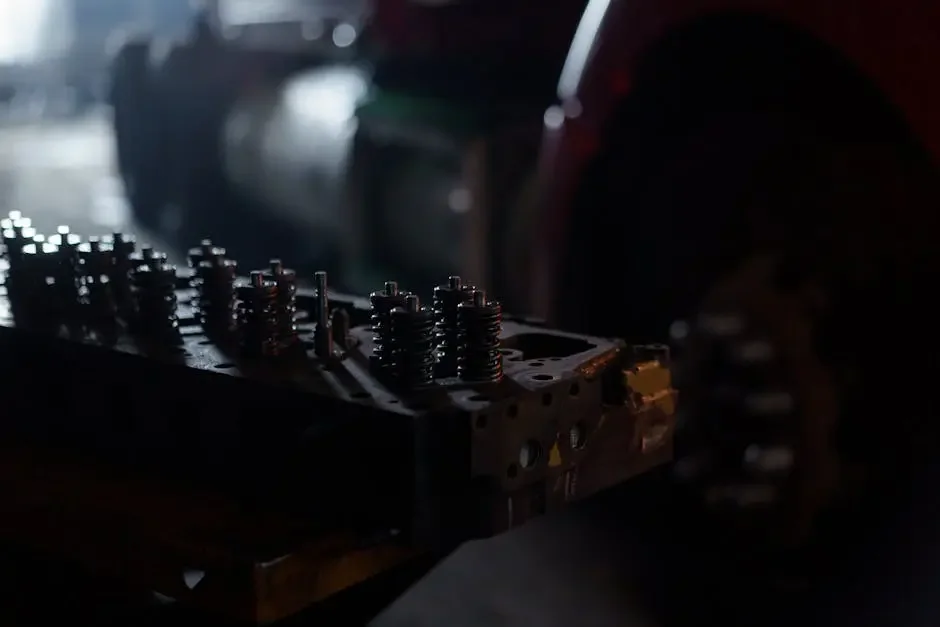

What is Cylinder Honing?

Cylinder honing is a machining process used to improve the surface finish of engine cylinders. This technique involves using specialized tools to create a crosshatch pattern on the cylinder walls, which helps retain oil and facilitate proper piston movement.

But why does this matter? The surface finish directly affects the way piston rings seal against the cylinder walls, which is crucial for engine efficiency. A well-honed cylinder allows better lubrication, minimizes wear, and ultimately leads to smoother engine operations. Without honing, the cylinder can develop a rough texture that could cause unwanted friction.

In essence, honing is not just about polishing; it’s about preparing the engine for longevity. Think of it as giving your engine the best possible start. By understanding what cylinder honing entails, you can appreciate how this process directly correlates with overall engine health.

How Cylinder Honing Contributes to Engine Longevity

By ensuring a proper surface finish, honing reduces friction between the piston rings and cylinder walls, leading to less wear and tear. This process not only extends the life of the engine but also enhances its fuel efficiency. A smooth finish means that the engine doesn't have to work as hard, which translates to better performance.

Moreover, cylinder honing aids in improving combustion efficiency. With a fresh hone job, the air and fuel mix can combust more efficiently, which means more power for your engine without the additional strain. It also leads to cleaner emissions, making it good for both your vehicle and the environment.

In addition to performance, consider the economic benefits. Preventive maintenance like honing can significantly reduce repair costs down the line. It’s often cheaper to hone a cylinder than to replace it or undertake a complete engine rebuild. With an understanding of how honing contributes to engine longevity, it’s clear that this practice is an investment in your vehicle’s future.

The Cylinder Honing Process Explained

Understanding the honing process can demystify why it’s so important. This section will walk you through each step, from selecting the right tools to performing the actual honing technique. The process typically begins with assessing the condition of the cylinder, measuring any wear or damage that may have occurred.

Once the assessment is complete, it's crucial to choose the right honing tool. Different engines might require different grits or sizes. The next step involves the honing itself, where the tool is used to apply a consistent pressure on the cylinder wall, creating that much-needed crosshatch pattern.

But honing isn’t just about the speed; it requires precision. Each pass of the honer must maintain a consistent angle and depth to ensure that the finish is uniform. After honing, the cylinder undergoes a cleaning process to remove any debris or oil residues before reassembly. Understanding these steps can enhance your appreciation for the craft involved in maintaining your engine.

Signs Your Engine Might Need Honing

Recognizing the signs of wear in your engine can save you from more serious issues later. Look out for symptoms such as increased oil consumption, loss of compression, and unusual noises from the engine. These warning signs indicate that the tolerances within your engine may no longer be optimal.

Additionally, if you notice a decrease in performance or a sudden drop in fuel efficiency, it could be time to consider honing. These issues often stem from friction and wear caused by improper sealing and surface texture. Ignoring these signs might lead to more significant damage that could require expensive repairs.

It's always better to act proactively. Regular maintenance, including checking for these signs, will allow you to stay ahead of potential issues. With awareness and timely action, honing can drastically improve your engine's performance and longevity.

Frequently Asked Questions About Cylinder Honing

From how often you should hone your engine to the best techniques used, this section answers common questions to help you feel more informed and empowered regarding your engine’s maintenance. On average, many mechanics recommend honing every 50,000 to 100,000 miles, but this can vary based on driving conditions.

You might also wonder about the techniques used during honing. There are several methods, including plateau honing, which helps provide an optimal surface finish. Understanding these options can help you make better decisions when caring for your engine.

Moreover, don't hesitate to ask your mechanic about their honing practices. Transparency can give you confidence in the decision-making process and help ensure that your car receives the best care possible. Armed with this knowledge, you can approach your vehicle’s maintenance with a renewed sense of confidence and empowerment.

The Importance of Cylinder Honing for Your Engine’s Health

In conclusion, cylinder honing is not just a maintenance task; it's a vital procedure that can extend the life of your engine and enhance its performance. By prioritizing the honing process, you ensure a smoother operation and reduce the likelihood of costly repairs down the line. Remember, a well-maintained engine is a happy engine, and honing is a key part of that maintenance.