How Does Surface Grinding Improve Engine Longevity?

Surface grinding is a crucial process in engine maintenance and longevity. By creating a finely finished surface, it enhances various elements of engine performance, helping your vehicle run smoothly for years to come. In this guide, we’ll explore the essential steps of surface grinding and how it contributes to engine longevity.

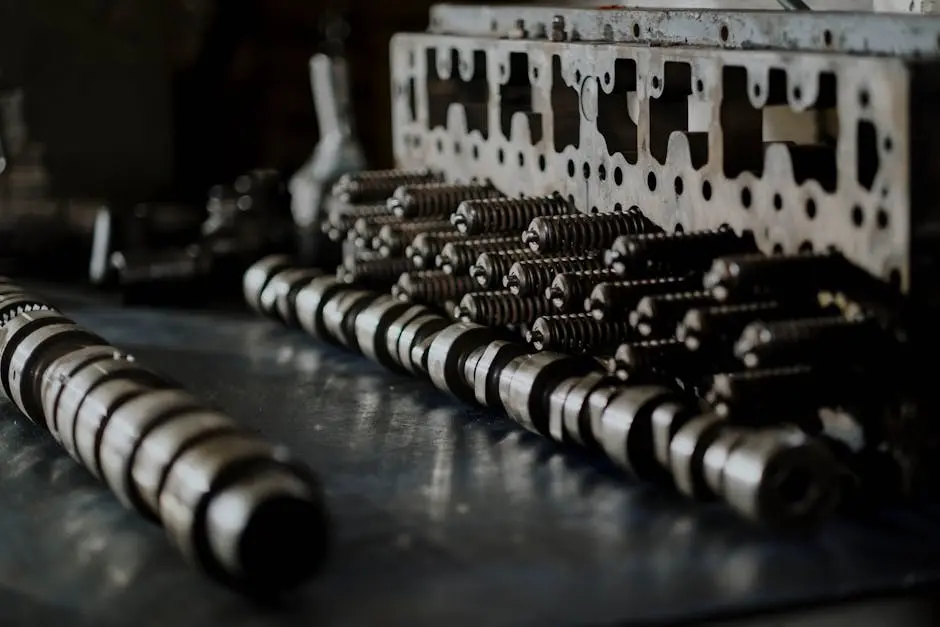

Understanding Surface Grinding

Surface grinding involves removing material from a workpiece to achieve a smoother, more accurate finish. This process is vital for improving engine components' fit and function.

At its core, surface grinding is an intricate form of machining that emphasizes precision. It employs specialized grinding wheels to ensure that the surface of an engine part is uniformly leveled and finished. With this level of detail, engine parts can interact more seamlessly, contributing to the overall harmony of engine operation.

Moreover, understanding the nuances of surface grinding can illuminate its importance in the broader context of engine maintenance. From the selection of the right abrasives to the control of grinding speeds, every detail matters. This meticulous approach transforms engine parts from rough and uneven to incredibly smooth, which lays the foundation for enhanced performance.

The Benefits of a Smooth Surface

A smooth surface reduces friction between engine parts, leading to lower wear and tear. This directly impacts engine longevity and overall vehicle performance.

When friction is minimized, not only does your engine operate more efficiently, but it also experiences less heat buildup. High temperatures can lead to premature failure; thus, a smoothly ground surface crucially aids in regulating engine heat. In essence, your engine becomes a well-oiled machine, working harmoniously without the constant battle against friction.

Additionally, smoother surfaces are more resilient to external forces. They can better withstand the daily stresses that come with driving, which ultimately translates to a longer-lasting engine. Think of it this way: with every mile you drive, a well-finished engine part is actively protecting itself against degradation.

Prevention of Corrosion and Wear

Surface grinding helps in preventing corrosion by creating a surface that is less prone to rust and other damaging elements. This protective effect is essential for parts that are exposed to harsh conditions.

By utilizing a surface grinding process, you can effectively enhance the durability of engine parts, particularly those constantly exposed to moisture and adverse environmental conditions. Such treatments create a barrier that deflects potential corrosion agents, giving your engine the longevity it deserves.

Moreover, the grind itself can eliminate any pre-existing imperfections that might otherwise trap moisture or contaminants, setting the stage for a robust defense against rust. In the long run, this means that you’re less likely to encounter costly repairs due to corrosion-related damage.

Achieving Precision in Engine Parts

Precision is key to engine performance. Surface grinding allows for tighter tolerances in fitting engine components, which can greatly enhance their functionality and lifespan.

When every part fits perfectly, the risk of mechanical failure diminishes significantly. Tighter tolerances mean that each engine component interacts smoothly without unnecessary gaps that can lead to leaks or wear. It's the difference between a finely tuned instrument and a bulky assembly line product.

Furthermore, this level of precision ensures that all engine parts can work in concert, optimizing fuel efficiency and power output. Think of it as tuning an orchestra; each part must harmonize to produce the best results. That’s what surface grinding achieves: a well-tuned engine that runs smoothly for an extended period.

Regular Maintenance and Surface Grinding

Incorporating regular surface grinding into your maintenance routine can lead to significant improvements in engine health, reducing the likelihood of major repairs as the vehicle ages.

Just as frequent tune-ups prolong the life of a car, scheduled surface grinding acts as a proactive approach to engine care. During these grinding sessions, not only are you refining the surface of the parts, but you're also able to identify any developing issues before they escalate.

Consider this: routine surface grinding helps to maintain that crucial smoothness, ensuring that your engine's performance remains optimal throughout its life. It’s an easy step to incorporate into your maintenance schedule that can make a world of difference–one you certainly won't want to overlook.

Final Thoughts on Surface Grinding for Engine Longevity

In conclusion, surface grinding is more than just a technical process; it’s a significant investment in your engine's lifespan. By understanding and implementing this technique, you can ensure better efficiency, reduced wear, and a longer life for your vehicle.