How Does Cylinder Head Machining Affect Engine Longevity?

Understanding the impact of cylinder head machining on engine longevity is essential for any car enthusiast or mechanic. In this article, we will explore the steps involved in the machining process and how these can influence your engine's overall health and lifespan.

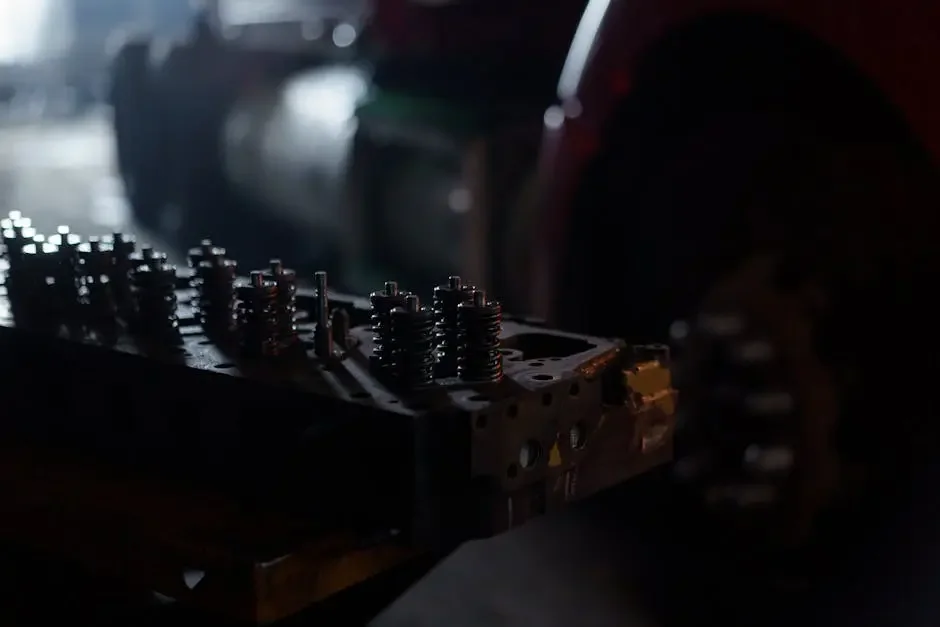

Understanding Cylinder Head Machining

>Learn the basics of what cylinder head machining involves and why it's important for engine performance.

At its core, cylinder head machining is about precision. This process involves reshaping and refining the cylinder head to enhance the overall functionality of an engine. By maintaining surfaces that are flat and true, the sealing process for the head gasket becomes more effective, which prevents leaks and improves combustion efficiency.

This is crucial because the cylinder head and its components play a pivotal role in controlling the engine's airflow, fuel intake, and exhaust system. A well-machined cylinder head ensures smoother airflow, improving the engine’s performance and efficiency.

Moreover, a properly machined head can prevent warping, which can occur due to high temperatures and pressure within the combustion chamber. Warping leads to misalignment and can cause significant engine problems if left unchecked.

Why Machining is Necessary

>Discover the common reasons for machining and the specific issues it addresses in an engine.

Machining is often necessitated by wear and tear over time. For instance, as engines run, heat and pressure can warp the cylinder head, resulting in sealing issues that prevent the engine from running efficiently. If neglected, this can lead to significant engine damage and reduced longevity.

Another reason for machining is to correct previous botched repairs. If an engine has undergone previous work and the cylinder head wasn't properly machined, performance can suffer greatly. A thorough machining process rectifies these inadequacies, ensuring a solid foundation for optimal performance.

Additionally, if you’re upgrading components like pistons or valves, machining becomes necessary to accommodate new parts. It’s about creating a cohesive working environment within the engine, tailored to its specific needs and the new performance targets.

The Machining Process

>An overview of the steps involved in the cylinder head machining process and the expected outcomes.

The machining process typically starts with the inspection of the cylinder head for any visible damage or imperfections. Once assessed, the head is cleaned thoroughly to remove any buildup of carbon or sludge that could interfere with the machining.

Next comes the actual machining, which can involve several techniques such as milling and resurfacing. This process trims down the surfaces, ensuring they are perfectly flat and true. This is critical because an uneven surface can lead to problematic sealing and airflow issues during engine operation.

After machining, it’s not just about putting everything back together. The reassembly process is equally crucial, as it involves ensuring that all components are correctly aligned and tightened to manufacturer specifications. This attention to detail can significantly prolong an engine’s life.

Impact on Engine Longevity

>Explore how proper machining techniques contribute to the durability and lifespan of an engine.

Proper cylinder head machining directly contributes to engine longevity by improving its thermal efficiency. With a correctly finished surface, the engine can maintain optimal temperature and pressure levels, reducing the likelihood of overheating and subsequent damage.

Moreover, accurate machining allows for better compression ratios within the engine, enhancing power output while also improving fuel economy. This means that not only is the engine more powerful, but it consumes fuel more efficiently, extending its operational life.

In essence, every aspect of engine performance is interlinked, and a well-machined cylinder head lays the groundwork for a robust and enduring engine. Like a solid foundation for a home, it’s what makes everything else function smoothly.

Common Mistakes to Avoid

>Identify typical errors made during machining and how they can negatively affect engine longevity.

One of the biggest mistakes in cylinder head machining is not checking for warpage before starting the process. Neglecting this step can lead to inadequate results and further complications down the line, ultimately affecting engine life. A flat and true surface is critical.

Another common error is rushing through the machining process. Quality takes time, and cutting corners can lead to oversights that might not become apparent until the vehicle is back on the road, resulting in worse performance or major engine failures.

Lastly, one must be cautious about using the wrong tools or settings for specific cylinder heads. Every engine is unique, and using incorrect techniques can lead to catastrophic issues, negating all the benefits that proper machining could provide.

Maintaining Your Engine Post-Machining

>Tips on how to take care of your engine after cylinder head machining to maximize its lifespan.

Once the cylinder head machining is completed, it’s important to allow the engine to break in properly. Follow the manufacturer's guidelines for break-in periods, which typically involves gradual acceleration, avoiding high RPMs for the first few hundred miles.

Regular maintenance is also key following machining. Keep an eye on coolant levels and ensure the engine does not overheat. Regular oil changes and inspections will help catch any issues early on, which can save you money and heartache in the long run.

Lastly, don't forget to listen to your engine. Any unusual noises or performance changes could signal an issue that needs immediate attention. Building a relationship with your vehicle and being attentive can greatly increase engine longevity post-machining.

Final Thoughts on Cylinder Head Machining and Engine Longevity

In conclusion, proper cylinder head machining can significantly enhance engine longevity by ensuring optimal performance and minimizing wear. It's crucial to approach this process with care and expertise to reap the full benefits.