How Does Crankshaft Grinding Affect High-Performance Components?

Crankshaft grinding is an essential process in maintaining and enhancing engine performance, especially for high-performance components. In this blog, we will explore how this procedure impacts the overall functionality and efficiency of engines designed for high performance. If you're curious about the mechanics behind crankshaft grinding and its significance, keep reading!

What is Crankshaft Grinding?

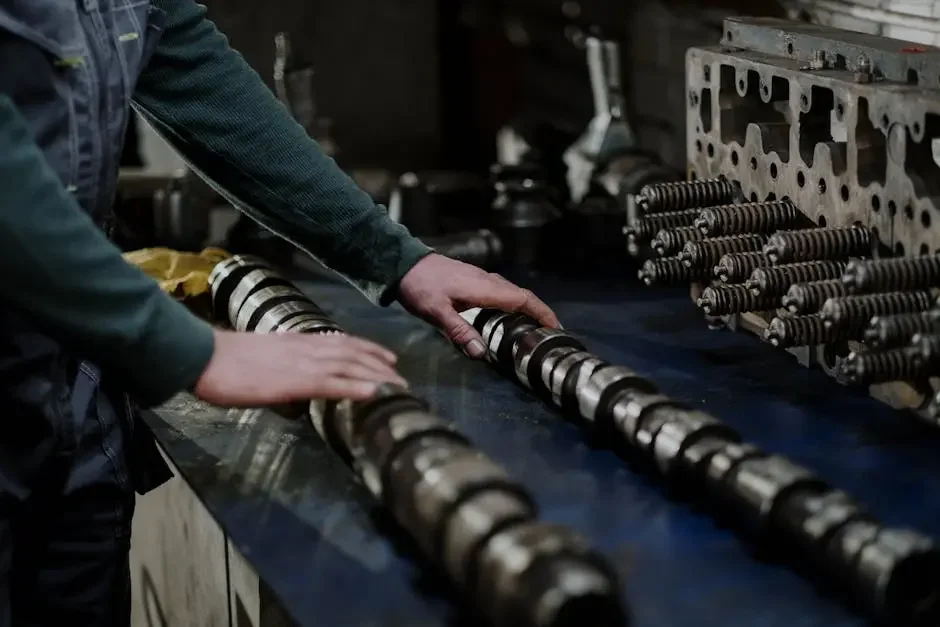

Crankshaft grinding is a machining process used to restore the crankshaft's surface to its original specifications. This is crucial for maintaining the performance of high-performance engines.

The process involves removing material from the crankshaft to achieve a smooth, even finish. This not only enhances the aesthetic aspect but also significantly improves the operational efficiency of the engine.

In high-performance vehicles, every detail counts. Crankshaft grinding ensures that the engine runs more smoothly and produces better power output by optimizing the crankshaft's geometry.

Ultimately, crankshaft grinding is not just about repairs; it's about ensuring that the engine can perform at its absolute best, especially under high-stress conditions.

Why is Crankshaft Grinding Important for High-Performance Engines?

For high-performance engines, precise crankshaft dimensions are vital. Grinding helps in reducing friction and ensuring optimal performance.

Effective crankshaft grinding contributes to better power delivery. When a crankshaft is ground correctly, it minimizes the chances of vibrations that can disrupt engine performance.

Additionally, precision grinding maintains the alignment of the crankshaft, which is essential for high-performance applications where every bit of efficiency counts.

Moreover, with high-performance engines, you’re usually pushing the limits. Therefore, ensuring every part, including the crankshaft, is in prime condition makes all the difference.

How Does Grinding Affect Tolerances and Clearances?

Proper crankshaft grinding ensures tight tolerances and clearances, which are essential for maintaining engine efficiency and preventing component wear.

When tolerances are correctly measured and maintained, the crankshaft rotates more freely. This smooth operation significantly reduces wear and tear on both the crankshaft and surrounding components.

Moreover, clearances that are too tight or too loose can lead to inefficiencies in the engine's operation, resulting in power loss and increased fuel consumption. Therefore, accurate grinding is vital.

Every micron counts! As high-performance enthusiasts know, even the smallest discrepancies in clearances can lead to significant changes in performance. Proper grinding helps avoid these pitfalls.

What are the Effects on Power and Torque?

Crankshaft grinding can increase an engine's power and torque by ensuring the crankshaft can rotate smoothly, leading to better combustion and energy efficiency.

A well-ground crankshaft reduces friction, which means more energy can be transferred to the wheels instead of being lost to heat and wear. This is especially critical in competitive racing scenarios.

By optimizing the crankshaft, you're able to unlock the engine's true potential, leading to not only improved power and torque but also a more responsive and fun driving experience.

In the world of performance tuning, crankshaft grinding is often one of the first modifications considered. It's a key step in maximizing the performance of any high-performance setup.

Can Improper Grinding Damage High-Performance Components?

Yes, improper crankshaft grinding can lead to misaligned components and increased friction, ultimately damaging high-performance parts and degrading engine function.

When the grinding process is done incorrectly, it can compromise the structural integrity of the crankshaft, leading to cracks or premature failure. This not only affects the crankshaft but also jeopardizes other critical engine components.

Furthermore, misaligned parts can cause serious vibrations, which may threaten the longevity of the entire engine. Therefore, ensuring that grinding is performed by a skilled technician is paramount.

Ultimately, the risks associated with improper grinding can far outweigh any short-term cost savings you might expect. Investing in high-quality workmanship is crucial for maintaining high-performance components.

Key Takeaways

Understanding the nuances of crankshaft grinding can greatly impact the performance of your high-performance components. By ensuring proper grinding techniques and measurements, drivers and engineers can harness maximum power and efficiency from their engines.